Your Cart is Empty

A Gem Cutting Adventure

Haven’t you always wondered how those colorful pebbles are turned into sparkling gems? This summer, our Sustainability Manager, Evi, went on a trip to Sri Lanka to learn more about gem-cutting. This helped her understand the process, as well as the risks. I’ll let her take over and tell you her story.

Working on making Gardens of the Sun a more responsible and sustainable business, I felt the need to know more about the raw materials we work with every step of the way.

Traceability is a key part to creating an ethical brand. One aspect of our journey that I had little to no idea about was the shaping of raw gemstones.

When the opportunity for a gem cutting course opened up, I leapt at it. And the opportunity to visit Sri Lanka was an added bonus! I landed in Colombo, and hopped on a bus for a 4-hour trip to Rathnapura.

My course would be 5 days long, and I knew I would be working on quartz, learning how to cut, shape, facet, and polish it.

Beyond that, I had very little idea of what it would actually entail.

The experience of cutting the quartz was an eye opener. I didn’t realize how much of the stone was cut away! We lost two thirds of the stone weight in the cutting process. I worked on three pieces of quartz. With a little help, I turned those three pieces into a brilliant cut, a flower cut, and a cushion cut. Out of the three, the flower cut was the most complicated one. It was also my favorite - it's incredibly beautiful!

I’ve always known that the hardest substance on earth is a diamond, but during the course I learned that sapphires (the national pride of Sri Lanka) are second on the list. It makes sense that it’s the second favorite choice for engagement rings.

The changing light outside became a companion that told me how slow the process was. To transform a relatively large quartz took me around eight hours. The master cutter admitted that for him, it would take a mere 2 hours on average to cut a stunning 2 carat stone.

He laughed when I lamented my slow speed, and told me, “I’ve had years of practice. I also started slowly. These days if it takes me one day to make a single stone – I wouldn’t be able to make a living!”

It took 100% of my concentration to cut and shape the quartz. Even then I had to get my stone fixed, because I cut it the wrong way. Not only does gem-cutting require intense concentration and patience, it also needs a high level of accuracy. I was working on a sizable stone – I can’t imagine having to work on the dainty size of the gems we usually use in our jewelry!

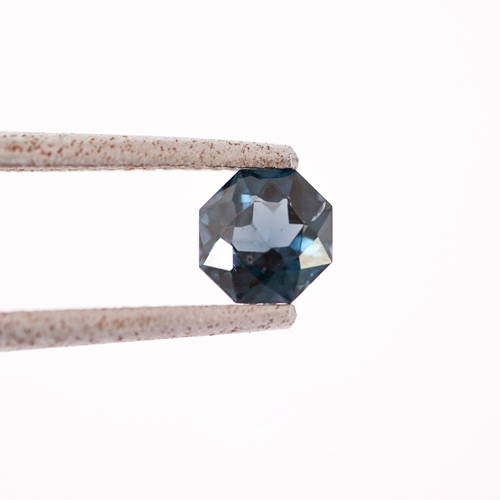

During my time in Sri Lanka, I also took the time to look around the road in Rathnapura known for its gemstone stores and dealers. Hopping from shop to shop, I was absolutely floored. Met with an array of glittering gemstones I could feel my pulse quicken. I understood why Meri finds it hard to resist buying everything in front of her when she’s off to find gems for Gardens of the Sun! I cooed over trays of sapphires in different cuts and sizes, colorful spinel in every shade imaginable, and garnets that caught the light in the most enchanting ways.

Now that I'm armed with the knowledge of how chunks of stone can be transformed into these jewels, I realize I've only scratched the surface of how much work goes into shaping and polishing the stones I look at every day at work.

I look forward to learning more about gem cutting, and the creative cuts!

For instance, have you seen some of the really cool, intricately cut spinel we have?